Remarks1.Thesingle-spacetensionandcompressionmachineisanewtypeofmicrocomputer-controlledservotensionandcompressiontestingmachine,independentlydevelopedbyourcompany.2.Thismachineisdesignedtostretch1000KN,compression200

Remarks

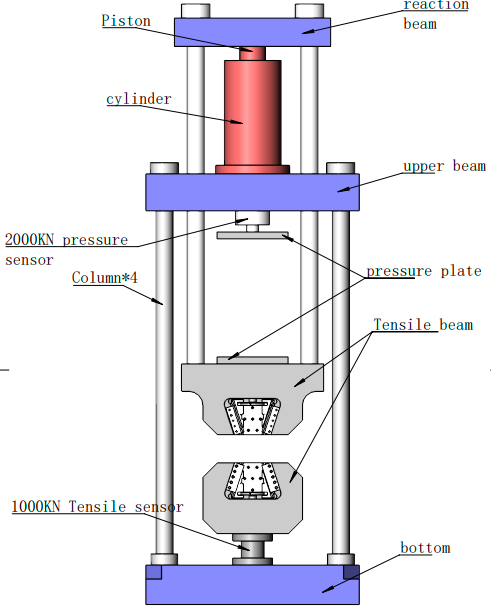

1. The single-space tension and compression machine is a new type of microcomputer-controlled servo tension and compression testing machine, independently developed by our company.

2. This machine is designed to stretch 1000KN, compression 2000KN, dual sensor design, stretching and compression and Bending can be realized independently.

3. The oil cylinder is top-mounted, servo oil source control, independent controller.

I. Introduction

This testing machine integrates automatic control, automatic measurement, data acquisition, screen display, and test result processing. It uses the upper cylinder host as a platform, and is equipped with precision oil pumps, electro-hydraulic servo valves, and PC servo controllers to achieve multi-channel closed-loop control. , Complete automatic control, automatic measurement and other functions of the test process. It has the characteristics of good professionalism, high reliability, and easy upgrade. It can be continuously enriched with the development of test machine measurement and control technology and changes in test standards.

This machine is mainly used for tensile and compression performance tests. It can draw time-test force, time-displacement, displacement-test force curves according to test requirements and automatically process test data.

The main engine adopts the structure of upper cylinder and column frame, and the frame adopts high-strength steel plate welding and aging treatment, which has the characteristics of high strength and small deformation. The beam and the workbench are connected to each other through the column assembly, thus forming a force-bearing mechanism. The oil cylinder is fixed in the center of the upper beam, and a stretching fixture is installed on the piston. Cylinders and pistons are the main parts of the main engine. Their contact surfaces are precisely processed to maintain a certain fit clearance and a proper oil film. The pistons can move freely while minimizing friction.

II. Features

1. Precision load frame with no gaps, high rigidity and high stability, lengthened size can be customized. The column assembly, beam, and workbench are all welded with high-strength steel plates. After aging treatment, they are processed and precisely ground by a machining center to ensure parallelism and perpendicularity.

2. Multiple closed-loop control methods such as automatic load holding, stress and strain control, cycle control and self-programming control.

3. High-precision wheel spoke load cell, with wide linearity, good stability, and guarantee the accuracy of load measurement.

4. The circuit board adopts photoelectric isolation design with strong anti-interference ability.

5. Using a brand computer, equipped with Windows hydraulic testing machine special measurement and control software, according to national standards or standards provided by users, the tensile properties of various materials are measured. The data acquisition, processing, analysis, storage and display of the test process are all completed by a microcomputer, and the measurement results are accurate and reliable. The test data is counted and processed again, and then various required test curves and test reports are output and printed. It is equipped with test curve amplification, comparison, and traversal functions, which are intelligent and convenient. All-digital closed-loop, multi-channel, multi-function, easy-to-operate measurement and control software; a variety of test methods and standards (ASTM, ISO, DIN, EN, BS, etc.) are available in the database; a powerful test database is built by itself, and the test data is available at any time Save, query, call, and realize data transmission and conversion with the user's local area network and the Internet.

1) Automatic control of test process, real-time control and display of test force, peak value, deformation, displacement, test curve, full keyboard input operation and intelligent setting system of control mode; arbitrary setting of control mode, no impact, smooth switching, loading and unloading smooth.

2) Flexible Excel, Word reports, default format and self-editing format; multiple sorts, multiple types of output. The professional software of the testing machine can realize data and indicators such as compressive strength (Rm). The control and data processing of the test process by the computer control system meets the requirements of the corresponding national standards for metal materials and non-metal materials, and the test reports are diversified.

3) It can re-read the completed test, simulate reproduction, data re-analysis, multi-curve superposition, and comparison traversal.

4) The test curve can choose the coordinate axis arbitrarily, and it can be zoomed in and out freely; multiple curves can be displayed at the same time, and the required coordinates can be set, such as: load-time, load-displacement, stress-strain, etc., full-scale self-adjustment.

5) Modular and open programming to meet individual requirements. With prompt and wizard functions.

6) Automatic return after the test, intelligent, efficient and fast.

6. Multiple protection functions: test force overload protection; overcurrent and overvoltage protection; safety protection when the sample is broken; operation prompt guide protection; automatic protection at the end of the test, etc.

7. Hydraulic system: The hydraulic system of this machine is easy to operate to ensure safety. The appearance of the testing machine is neat and beautiful. The height of the control part and the indicator part are appropriate, which is convenient for the experimenter to operate and observe. The hydraulic oil in the hydraulic oil station is driven by the motor to drive the high-pressure pump into the oil circuit, flows through the one-way valve, the high-pressure oil filter, the differential pressure valve group, and the servo valve, and enters the oil cylinder. The computer sends a control signal to the servo valve to control the opening and direction of the servo valve, thereby controlling the flow into the cylinder, and realizing the control of the constant velocity test force.

8. This equipment will be equipped with a fully enclosed protective cover to avoid damage to the experimenter after the sample is broken.

9. Due to the height of this equipment is 3500mm, we will be equipped with a trapezoidal operating platform, which is convenient for experimenters to place samples.

III. Calibration System

The oil source is controlled by an electro-hydraulic servo, a fully digital PC servo controller, an electro-hydraulic servo valve, a spoke load sensor, a photoelectric encoder for measuring displacement, a special PC measurement and control card for the testing machine, a printer, a multi-function test software package, and an electrical control unit And other parts of the composition.

IV. Standard electro-hydraulic servo control oil source

1) It is a load-adapted fuel inlet throttle speed control system, which adopts mature technology and is designed and manufactured according to standard modular units, and is specially designed for use with a computer-controlled hydraulic universal testing machine;

2) Choose oil pumps and motors with excellent performance, with reliable quality and stable performance;

3) The load-adaptive throttle speed control valve developed and produced by our own unique technology has stable system pressure, self-adaptive constant pressure difference flow adjustment, no overflow energy consumption, and easy PID closed-loop control;

4) Piping system: The pipelines, joints and their seals are selected as a set with stable performance to ensure that the hydraulic system is sealed reliably and there is no leakage of oil.

V. Electric control cabinet

1) All the strong current components of the system are concentrated in the strong current control cabinet to realize the effective separation of the strong current unit and the measurement and control weak current unit to ensure that the measurement and control system is not disturbed and works stably for a long time;

2) Manual operation buttons are set on the electric control cabinet, including power switch, emergency stop, and oil source oil pump on and off.

VI. High resolution digital controller

1) The system is based on PC computer, fully digital PID adjustment, equipped with PC card board amplifier, measurement and control software and data acquisition and processing software, which can realize the closed-loop control of test force, sample deformation, piston displacement and smooth switching of control modes ;

2) The system consists of three signal conditioning units (test force unit, cylinder piston displacement unit, specimen deformation unit), control signal generator unit, electro-hydraulic proportional valve drive unit, electro-hydraulic proportional oil source control unit, and necessary I/ O interface, software system, etc.;

3) The closed-loop control loop of the system: the measuring sensor (pressure sensor, displacement sensor), the electro-hydraulic servo valve, the controller (each signal conditioning unit), and the control amplifier form multiple closed-loop control loops to realize the test force and cylinder of the testing machine The closed-loop control function of piston displacement and specimen deformation; has multiple control modes such as constant rate test force, constant rate piston displacement, constant rate strain, etc., and can realize smooth switching of control modes, making the system more flexible.

VII. PC board card type automatic control amplifier for testing machine

1) Pluggable PC board, using advanced computer bus control technology, specially designed for testing machines, with programmable analog amplifier, A/D conversion, digital acquisition channel, digital I/O, etc.;

2) The special measurement and control card and the PC form a single-card measurement and control system, which can be directly connected to the sensor for measurement, control and data acquisition, making the complex measurement and control and data acquisition system simple and reliable;

3) Using computer bus technology, directly plugged into the computer expansion slot, all digital circuits, zero adjustment, gain adjustment, etc. are realized through software, which is the latest product unit in the development of test machine measurement and control technology;

4) A cascade amplifier with programmable gain can get different gains of amplification;

5) The sensor bridge power supply and the reference voltage of the A/D chip share the same voltage, and the entire measurement system is attenuated year-on-year, realizing the hardware compensation technology of the bridge power supply;

6) Multi-bit A/D conversion meets the sensitivity and resolution requirements of the system, avoiding the software frequency multiplication method to reduce the characteristics of the system.

IX. Standard

ASTM E4, EN ISO7500-1, EN 10002-1,EN 10002-2, BS1610, DIN 51221

ASTM E83, ISO 9513, EN 3846 ve EN 1002-4,

EN ISO 12100:2010, EN ISO 13849-2:2012, EN ISO 13857:2008

EN ISO 13850:2015, EN 60204-1:2018, EN 61010-1:2010

EN 61000-6-2:2019, EN 61000-6-4:2019, EN 61326-1:2013

ASTM E290, ASTM C109

X. Product main configuration

List | Product configuration | Quantity |

1. | Main engine 2000kN (upper cylinder) | 1 set |

2. | Electro-hydraulic servo valve | 1 pc |

3. | Hydraulic oil source (main hydraulic parts) | 1 set |

4. | Testing machine software system | 1 set |

5. | Measurement and control system board | 1 set |

6. | Oil pump motor | 1 set |

7. | Oil pump | 1 pc |

8. | Displacement sensor | 1 pc |

9. | Control cabinet | 1 set |

10. | Load cell,1000KN and 2000KN | 2 pc |

11. | Computer (Intel processor with PCI expansion slot) | 1 set |

12. | Display (19LED widescreen) | 1 set |

13. | A4 printer | 1 pc |

14. | Hydraulic wedge-shaped stretching aids | 1 set |

15. | Jaw (φ13-26, φ26-40, L0-15, 15-30) | 1 set |

16. | Pressure plate (size 500*500) | 1 set |

17. | Random supporting tools, instructions, packing list | 1 set |

18. | Bending grip(3-point bending) | 1 set |

Other Test capabilities

a. Test for 7-Strand Wire

b. Test for Diamond wire mesh

c. Test other specimens

XII. Main technical parameters

Maximum tensile test force | 1000kN |

Maximum compression test force | 2000KN |

Effective measuring range of test force | 2%-100%F.S |

Test force measurement control accuracy | ±1% |

Hydraulic cylinder piston stroke | 800mm |

Column spacing | 800mm |

Maximum moving speed of piston | 0-50mm/min (stepless speed regulation) |

Displacement accuracy | Better than ±1% |

Displacement resolution | 0.01mm |

Indication accuracy of displacement measurement | ±1% |

Maximum stretching space | 800mm |

Machine size and weight (approximately) | 1200*900*3500,5000kg |

Control method | Electro-hydraulic servo full closed loop control, the control mode can be switched smoothly |

Screen display function | Force, displacement, deformation, curve, time, etc. |

Data processing function | Automatic collection, can analyze, save, query, print, etc. |

Protection function | Program and mechanical double protection |

Packing and transportation | Comply with JB/T 6147 of the Ministry of Machinery |

Chengyu Testing Equipment

Scan QR for more